Several major cities across the states have been carefully chosen as locations for these refueling stations. Their strategic placement aims to facilitate reliable and safe travel beyond California in fuel cell vehicles. The objective is to reduce the cost per kilogram from the current $36 to $15.

California has served as the primary hub for hydrogen infrastructure projects across the country, largely dominated by a single company, True Zero. The majority of refueling stations have been established by this company with minimal competition. However, HydroMAP intends to take a significant stride forward by establishing an affordable and dependable network of hydrogen refueling stations spanning the four southern states of California, Arizona, New Mexico, and Texas.

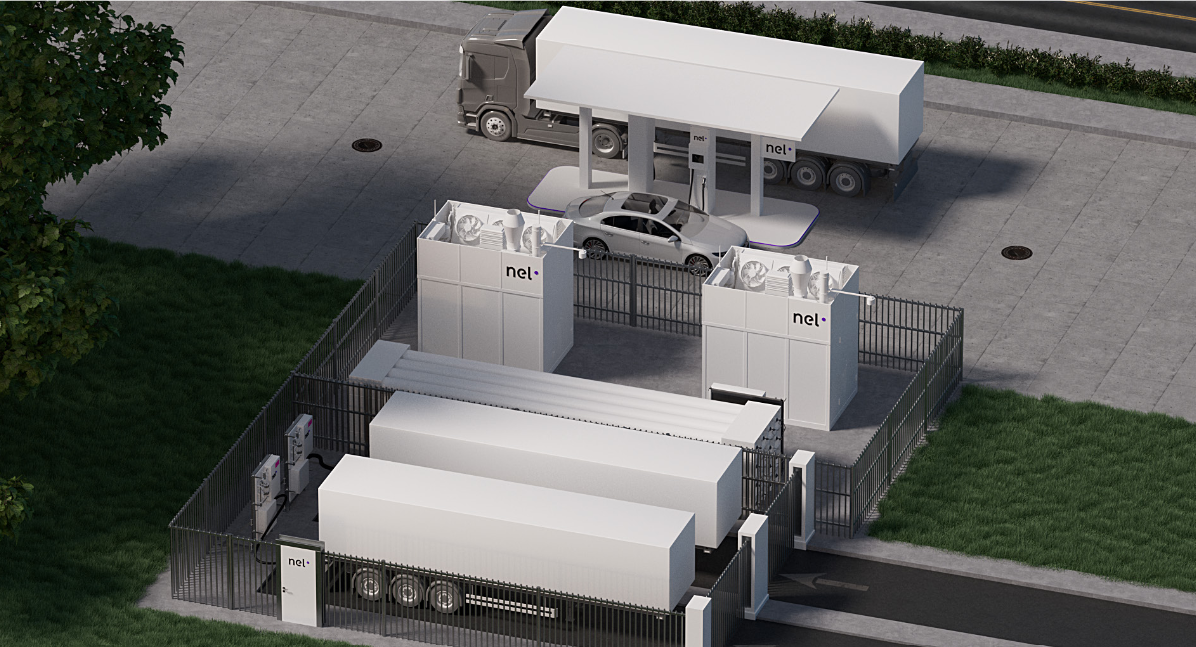

Layout

The layout of a hydrogen station is planned to be planned to based on the layout of a conventional gas station, in this way people will feel familiar with the concept even though is a completely new technology. In comparison to chargin an electric vehicle on which every owner of each charging station will need (in many cases) a profile created to just be able to charge the car. Therefore making the customer spend more time in addition to waiting for the vehicle to be fully charged or waiting for another EV to finish using the charger because the other chargers are offline. The typical layout of a hydrogen station better explain as shown bellow:

Courtesy: nelhydrogen.com/wp-content/uploads/2023/12/PM-TER-0031-EN.pdf

location and production methods

21 stations have been projected to be built in the strategically selected cities of: Los Angeles (3), Riverside (2), Indio (1), Blythe (2), Phoenix (3), Tucson (1), Wilcox (2), Lordsburg (2), Deming (1), Las Cruces (1), and El Paso (3).

Each refueling station is projected to supply at least a minimum of 500 kg of hydrogen per station, with multiple pumps available to keep an smooth experience for the customers.

Logistics

The methods of production of hydrogen are set to be 2; Steam Methane Reformer and Hydrolysis that uses natural gas for fuel production, and hydrolysis that converts water into hydrogen. From Arizona to Texas, Steam Methane Reformer method would be the preference of production. The cities of Phoenix, Tucson, Wilcox, Lordsburg, Deming, Las Cruces, El Paso, would have production of hydrogen through SMR since it is the easiest method to introduce the technology to the communities.

Los Angeles, Riverside, Indio, and Blythe are planned to produce hydrogen through hydrolysis. However, the problem is that California is currently having a difficult season of drought due to the lack of rain. Making it more difficult to the local communities that are scarce on water. Therefore, in the first phase of construction, these cities would produce hydrogen using the SMR method.

Production

For cities such as: Los Angeles, Riverside, Phoenix, Tucson, Las Cruces, El Paso will have a central production plant that will distribute the fuel to the stations. Each plant will be modular, in case that some components need to me maintained or fail, the plant is able to continue operating, perhaps at lower capacity but still able to remain online. For the first phase of the project, the logistics of the construction for the stations is to build the stations inside a regular gas station, like the current strategy that true zero implements in California. By doing as, the costs of construction will be substantially less than building a full-size refueling station, helping the expansion the infrastructure into more cities with ease.

Cities like Indio, Blythe, Wilcox, Lordsburg, and Deming will function as refueling stations and production plants. Since each station will be separated by a great distance of about 100 plus miles from the next nearest one, it poses a danger to travelers and local customers if the station goes offline. The reason is that the next biggest city would be too far away to send hydrogen to refill the reserves to maintain the station online. By having a minimum of 2 stations in each of these cities, in case one goes offline the other one will serve as back up, or if one production plant needs to be offline but the station can remain open, the plant from the other station would be able to supply the station that has its own plant offline.

Take a look at the current available infrastructure